The environmentally conscious world of Orsing

Why is Orsing going fossil free?

We believe that manufacturers of dental supplies can make a significant difference when it comes to global warming by reducing greenhouse gases in their production. In order to reduce our carbon footprint and curb global warming, it is important to reduce our use of fossil resources and our share of greenhouse gas emissions. By using bio-based polyethylene as raw material in products and packaging, the carbon dioxide level in the atmosphere can decrease, which is a significant factor for our planet and future generations. Switching more of our products to Green PE gives us a chance to offer what dental clinics are increasingly looking for: safe and sustainable consumables at a sustainable price.

Our packaging

Since plastic litter is an enormous problem across the globe, Orsing is constantly improving the packaging material used for its products. Our fossil – free products are packed in bio-based plastics and all Orsing´s items are shipped in FSC – certified carton boxes.

Why replace regular plastic with sugarcane-based PE?

The production of plastic uses an incredible amount of fossil fuels. Most estimates put the figure at around 8% of the world’s oil production, 4% of which is actually used in energy consumption to make plastic. To give you some idea, it takes about 1/4 of a liter of oil to produce a 1 liter water bottle.

Green PE significantly reducing carbon dioxide emissions compared to conventional PE. This ability to reduce the carbon levels of the atmosphere is higher than in any other biopolymer because of the high efficiency of the dehydration technology, the high capability of the polyethylene molecule to store carbon and as a consequence of the high biomass productivity of the sugar cane used both as feedstock (sugar) and energy source (bagasse). Due to the use of sugar cane bagasse as a raw material for the production of energy, a large part of sugar cane mills in Brazil are self-sufficient in terms of their energy needs.

Sugarcane bagasse is a co-product of the milling process through which it is separated from the cane juice, rich in sugars. Bagasse is used to fuel the boilers that generate steam and make the power generating turbines trigger. This energy fuels the plant itself, and when there is a surplus, it is sent to the local power grid and sold to supply cities.

The growing production of bioelectricity from bagasse combined with the broad use of ethanol make sugarcane the second-largest energy source in Brazil’s energy matrix, which is considered the cleanest in the world.

I’m green™ bio-based carbon footprint

Within the broader context of LCAs, the carbon footprint is a segment of the full assessment which focuses on greenhouse gases (GHG) emissions of I’m greenTM bio-based, Green PE. The carbon footprint allows Braskem and its clients to measure and lower their impact on our climate with increased precision.

As shown below, the emission per kg Bio-based Green PE is negative, -2.12 Kg CO2 per kilogram plastic, before transport from Brazil to Sweden. It means that for each kg of Green PE used, we absorb 2,12kg CO2 from the atmosphere. Mainly due to photosynthesis and the renewable sugarcane plant. For conventional fossil polyethylene, PE emission is 3,10 kg CO2 per kg, before transport from Saudi Arabia to Sweden.

Material-wise, the difference and the reduced CO2 emission is >5kg, when we replace one kg of conventional fossil PE with Green PE.

How efficient is Green PE production?

1 hectare (= 10 000 sqm football court!) of land gives approximately 82.5 tons of sugarcane. 82.5 tons of sugarcane gives 7200 liters of ethanol which produces 3 tons of Green PE.

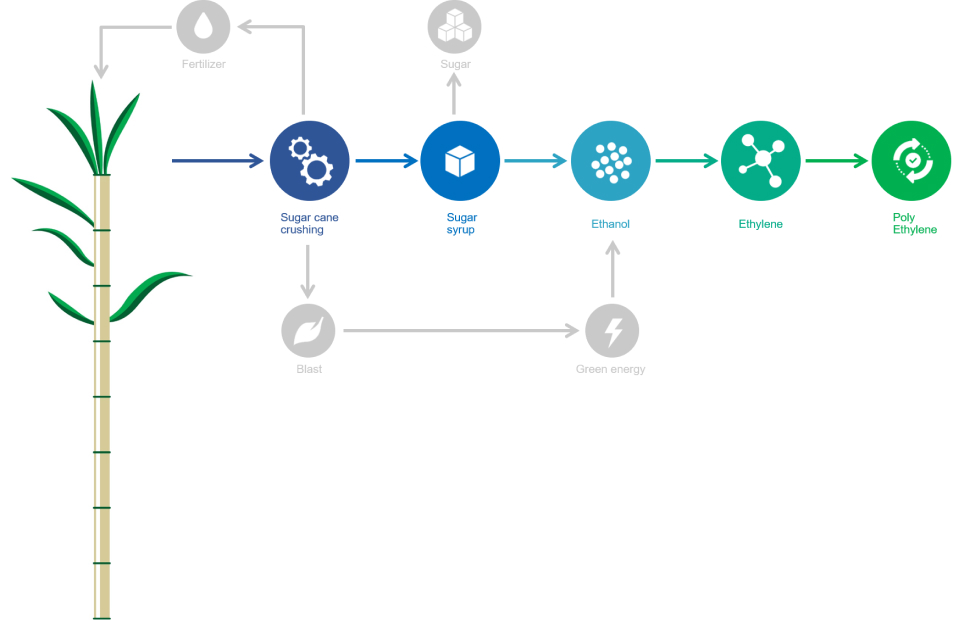

So how is Green PE produced?

Since the water requirements during the agricultural phase are supplied naturally by the rainfall in producing regions, sugarcane cultivation in Brazil is almost never irrigated. The use of water is concentrated in the industrial phase, mainly in sugar production, and on a very low scale.

Many mills adopt a fertigation system where the vinasse, which is a co-product of the ethanol production rich in organic nutrients and water, is brought back to the cane field. This organic fertilization reduces the need to use chemical fertilizers and therefore helps to reduce greenhouse gas emissions.

The ethanol from sugarcane in ethylene plants goes through a dehydration process and is transformed into green ethylene. The green ethylene then goes to the polymerization plants where it is transformed into Green PE.

Land use

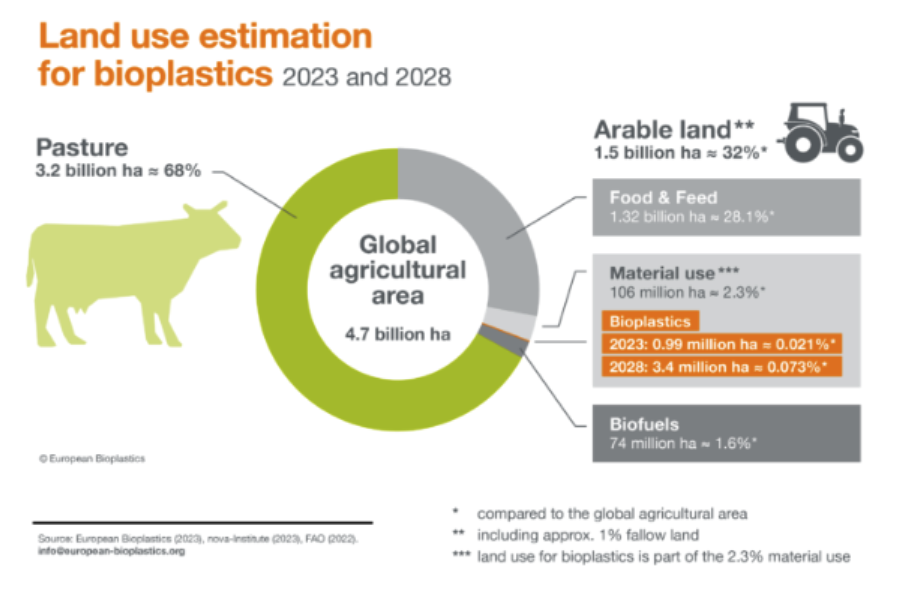

By now we already knoBioplastics are predominantly produced from agro-based feedstock (i.e., plants that are rich in carbohydrates) which is currently the most efficient way to produce bioplastics, as it requires the least amount of land to grow and produces the highest yields.

The huge difference between the land used for bioplastics and that for food, feed, and pasture shows that there is no competition between biomass use for food, feed and material use. Just about 0.021% of the global agricultural area is currently used to grow feedstock for bioplastics, while 96% is used for pasture and food/feed production.

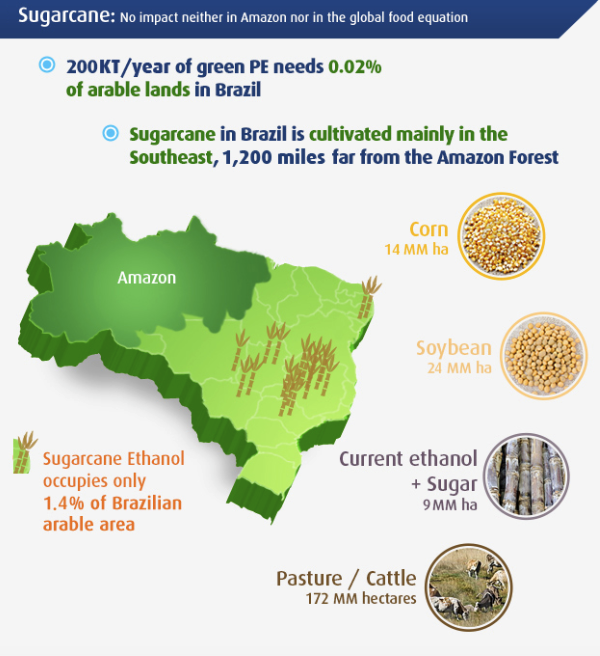

Is Green PE production affecting deforestation?

Sugarcane ethanol production currently occupies 4.6 million hectares of farmland, which is only around 1.5% of Brazil’s arable land. The sugarcane plantations where Orsing’s bio products have their origin are located in the South-Central and Northeast region of Brazil, more than 2,000 km (1,200 miles) away from the Amazon Region, which means that the plantations do not affect the rainforest or the global food equation. The expansion of areas used to plant sugarcane is governed by the Sugarcane Agroecological Zoning, a regulatory framework introduced by the federal government in 2009 that prohibits planting in areas of high biodiversity. The ethanol used to make the polyethylene is purchased from different suppliers that are selected according to a Code of Conduct for Ethanol Suppliers. The Code of Conduct covers aspects related to compliance with Brazilian labour law and respect for biodiversity. Orsing’s saliva ejectors and aspriator tubes in Green PE are produced from suppliers that strictly adhere to this Code of Conduct.

So much CO2 is saved by switching production from fossil plastic to Green PE at Orsing.

By replacing fossil plastic in the production of Bio line by Orsing, we will decrease our output of carbon dioxide in the atmosphere by 400 tons (2023).

How much is 400 tons of CO2?

400 tons corresponds to the CO2 emissions generated by driving 150 laps around the world with an average newly registered car in Sweden (2022).

(Circumference of the Earth = 40 075 km).

Some Basic Eco-glossary

Carbon Footprint

The total greenhouse gas emissions caused directly and indirectly by a person, organisation, event or product. A carbon footprint is measured in tonnes of carbon dioxide equivalent (tCO2e).

Renewable

Comes from nature and naturally restores or replenishes itself. It is constantly available without human or other outside influences. Sugar cane and bamboo are renewable resources.

Recyclable

Can be reused, transformed into a new item. A recyclable resource is one that can be used over and over but must first go through a process to prepare it for re-use. The process can be human-driven or naturally occurring. Glass and aluminium are examples of recyclable resources. Water can be considered a recyclable resource since it must go through the process of precipitation and evaporation in order to be reused. In addition, water can also be renewable in the form of hydroelectric energy. A waste-to-energy power plant combusts wastes such as Green PE and bamboo into electricity.

Biodegradable

Capable of undergoing biological anaerobic or aerobic degradation leading to the production of CO2, H2O, methane, biomass, and mineral salts, depending on the environmental conditions of the process. An important role in biodegradation is played by microorganisms, which are present in the environment and fed mostly by organic waste. However, unlike compostable, the term biodegradable means very little as everything is biodegradable given time. Thus, it is very important to specify the environment where biodegradation is intended to take place.

Compostable

Capable of breaking down by microbial digestion to create compost. Compost has many beneficial uses including improving and fertilizing soil. To go through a composting process, organic waste requires the right level of heat, water, and oxygen. In a pile of organic waste, there are millions of tiny microbes that consume the waste, transforming the organic materials into compost. In order to claim that a product is fully compostable, the product has to meet all the requirements in the European Norm EN 13432 and/or the US Standard ASTM D6400. Both specifications require that biodegradable/compostable products completely decompose in a composting setting in a specific time frame, leaving no harmful residues behind.

So why are Orsing’s bio products renewable and not recyclable/biodegradable/compostable?

Dental clinic wastes such as saliva ejectors and disposable mouth rinse cups that have been produced when treating patients are generally considered as biomedical hazardous wastes. Regulations differ from one country to another but due to their quantity, concentration and biological properties these wastes require special handling, most commonly disposal by incineration. There is therefore no value in producing recyclable/biodegradable/compostable saliva ejectors and cups while renewable materials with a carbon footprint close to 0 have tangible environmental advantages.

AND FINALLY…

Bio-based products are wholly or partly derived from materials of biological origin, excluding materials embedded in geological formations and/or fossilized. There is no common agreement on a minimal value yet due to varying regional regulations in Europe. In Japan an industry-wide commitment sets the “biomass margin” at “25 percent renewable material”. According to the USDA Bio-preferred Program, “the minimum share of renewable material ranges from 7 to 95 percent” depending on defined product category rules. This means that there is a jungle of ”bioproducts” in the world with very poor biobased carbon content, often as little as 15-20%. Orsing’s Green PE is certified as 100% fossil free by an independent body.

Sources

Braskem, European Bioplastic, Polymerfront AB, Orsing AB

https://www.carbontrust.com/resources/guides/carbon-footprinting-and-reporting/carbon-footprinting/;

https://sciencing.com/difference-between-renewable-recyclable-resource-5904510.html;

https://biobagworld.com/environment/biodegradable-and-compostable/